PC control software and PAC hardware to help you move quickly

Incentive Software Components for PC-based Control

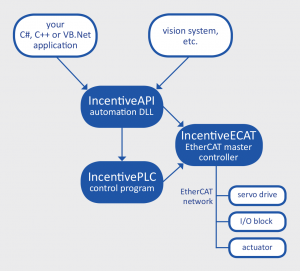

The Incentive family of software components runs on your standard PC hardware and creates a powerful and extensible control system for your automation project. The three primary members of this family are:

• IncentivePLC – a fast, multitasking controller offering powerful constructs to quickly implement a control program. IncentivePLC is programmed using the QuickBuilder programming environment, which can run either locally or on a remote system. For more information, refer to the QuickBuilder tab. More info…

• IncentiveAPI – this library of high-level automation functions lets your code, written in C#, C++ or VB.Net, interact with your IncentivePLC control program or directly with external sensors and actuators via IncentiveECAT. For more information, download the IncentiveAPI help file, which contains a full description of the objects and methods available via the API, along with usage examples in various languages. More info…

• IncentiveECAT – a software-based EtherCAT master controller, IncentiveECAT runs on one core of your multicore PC platform and uses a standard Ethernet port to communicate with up to 64 servo axes, or a combination of motion drives and I/O. Use it in conjunction with IncentiveAPI to give your own code easy access to controlling the physical world, or add IncentivePLC to build a complete PC-based control system. More info…

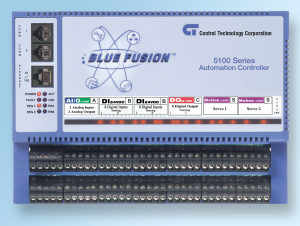

Series 5300 Programmable Automation Control Systems

Series 5300 programmable automation controllers are self-contained compact control systems featuring high-density I/O and an impressive suite of capabilities. With such powerful integrated capabilities as high-performance motion control, strong communications and data handling provisions, and a high-level automation-specific programming language, this series of product has become a favorite with fast-moving technology companies for their automation projects.

These systems are programmed using the QuickBuilder programming environment, a comprehensive programming tool encompassing programming, library creation, system configuration, debugging and monitoring. It fully supports all QuickBuilder language capabilities, which include multitasking, asynchronous events, user functions with parameters, and a modified state language structure that greatly improves program readability and performance.

The Series 5300 can operate standalone or in a distributed network, and is supported by a broad range of over 40 I/O modules, allowing you to tailor your I/O complement to specific device requirements without additional external hardware.

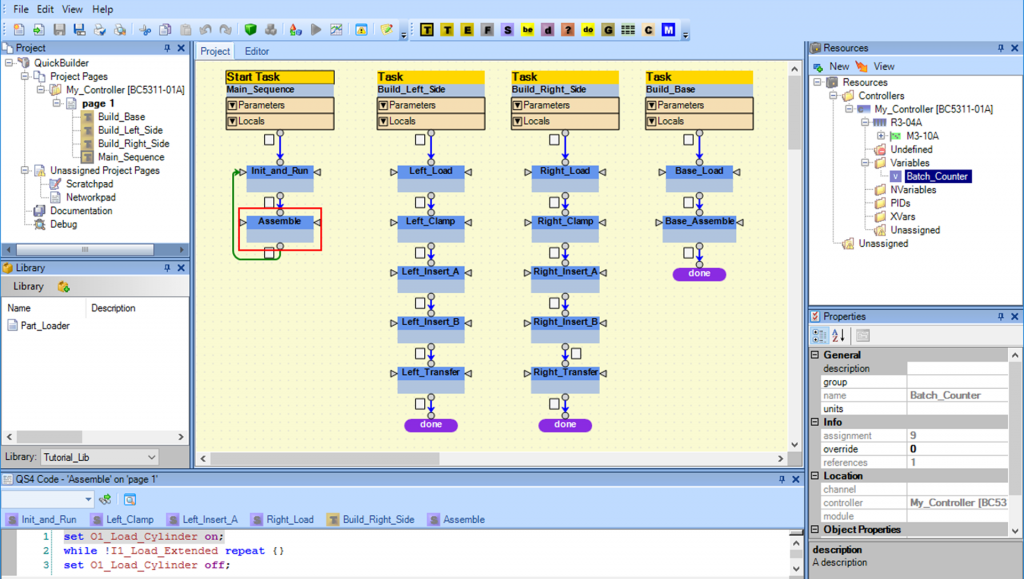

QuickBuilder – fast, maintainable automation programming

An advanced programming environment for both IncentivePLC and Series 5300-based systems, the QuickBuilder programming environment and QuickBuilder language combine to form the fastest path to project completion. Running on a standard Windows-based PC, the programming environment features graphical and textual program displays, text entry or syntax-directed editing,

Series 4400 and 5000 Touchscreens

Available in a variety of configurations, including NEMA4/IP65-rated front panels and memory capacities to 256MB, in screen sizes up to 15 inches. These touchscreens may be configured with EasyBuilder Pro user interface software, available as a free download.

Additional Families of Programmable Automation Control Systems

- High-density rack-mount system

- Integrates machine sequencing, motion control, networking, and data acquisition

- Up to 16 axes of motion

- Up to 512 I/O

- Serial and Ethernet communications

The 2700 Series programmable automation controllers use advanced technology, including a highly integrated plug-in CPU, to attain performance that exceeds the response metrics of much more costly systems. This performance level, combined with the controller’s up to 384K user memory capacity and extended I/O and step capacities, makes the 2700 Series appropriate for any application that demands ultra fast response times or real-time, multitasking machine control. A multi-processor architecture distributes the workload, thereby increasing system performance. Multitasking for up to 84 independent tasks and advanced motion control commands enable you to design sophisticated solutions for the most complex applications. Visit the CTC Support website to learn more.

MultiPro Programmable Automation Controllers

The MultiPro™ family of programmable automation controllers provides the tools you need to master your machine control projects easily. The single integrated environment minimizes training, and dramatically reduces engineering time. Total machine control in one package combines:

- high-performance multiprocessor design

- intuitive program development with the Quickstep™ for Windows™ State Language

- an extensive complement of automation features for amazingly fast implementation

Available in 13 preconfigured models, the MultiPro can be used for small applications requiring motion control, I/O, and user interface integration. Networking models are available; consult the Model Selection table on the CTC Support website for more details.

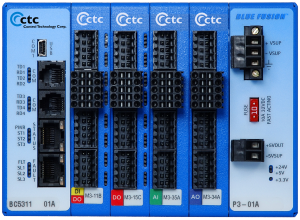

Series 5100 and 5200 Programmable Automation Controllers

These series combine configurable digital and analog I/O for up to 48 points, up to 6-1/2 axes of motion control, and enterprise connectivity into a single compact package. With built-in 10/100 Base T Ethernet, they support CTC’s binary protocol over TCP/IP and UDP, and Modbus/TCP. Other features include:

- Multitasking, up to 84 tasks

- Input linkable counters

- High-speed encoder input

- RS-232 and RS-485 ports

For more detailed information and datasheets, refer to the CTC Support site.

Model 2601 Programmable Automation Controller

The 2601 programmable automation controller is a high performance control system whose small size conceals a range of resources and capabilities usually found only in much larger and more costly systems. A few of this controller’s unusual features:

- Multitasking, with up to 28 parallel tasks running simultaneously.

- Fast State Language programming using Quickstep™.

- 988 storage registers, including 500 non-volatile registers.

- A Data Table capable of storing over 8000 numbers in a two-dimensional array.

- Two RS-232 communications ports.

- Internal counters which may be software-linked to any input.

For more information and to download a datasheet, visit the CTC Support website.